What To Know

- In northern Asia, whether in Japan, Taiwan or China, the rail in various forms, has empowered the people to thrive without the need to take commercial jets, and yet be able to reach much of the countries on land, especially where high-speed rail is available.

- “There is a trend for rail operators to move towards independence in operations, and having the systems to be able to run independently, operators and suppliers will need to provide products and solutions that can inter-operate with 100% compatibility and reliability, as well as future conformance to standards and preferences.

Editor’s brief: The rail is the most important infrastructure in many domestic supply chain implementations. In northern Asia, whether in Japan, Taiwan or China, the rail in various forms, has empowered the people to thrive without the need to take commercial jets, and yet be able to reach much of the countries on land, especially where high-speed rail is available. Likewise, in South East Asia, rail has evolved by leaps and bounds. In recent news, the Cikarang-Cikampek Rail in West Java, Indonesia, got a comprehensive safety upgrade through leading Indonesian rail systems provider PT Len Railway Systems and PT Len Industri, as well as leading German safety systems vendor HIMA. Read more below.

Singapore – The biggest Indonesian provider of railway application and safety systems, PT Len Industri (Persero), and its subsidiary, PT Len Railway Systems (LRS), have successfully upgraded the signaling and telecommunication system across the Cikarang-Cikampek rail service, at West Java, Indonesia, to conform to current and emerging safety standards.

“The rail industry is the critical bloodline for many economies and businesses in the Asia Pacific. Indonesia too, is building critical rail infrastructures to provide regional cities with efficient and cost-effective supply chain and consumer transportation. A complete and sustainable rail system includes infrastructure, signaling, operations, staff, and maintenance. As rail networks evolve and grow, rail suppliers and operators need to rise up to industry and global safety and cybersecurity standards to reduce risk and to assure stakeholders,” says Friedhelm Best, Vice President Asia Pacific, HIMA. “There is a trend for rail operators to move towards independence in operations, and having the systems to be able to run independently, operators and suppliers will need to provide products and solutions that can inter-operate with 100% compatibility and reliability, as well as future conformance to standards and preferences.”

PT Len Industri strengthens relationship with HIMA

In 2016, HIMA signed a significant strategic contract with PT Len Industri to upgrade the safety technology for 25 rail stations in Indonesia at a value of $1.8 million euros, which was HIMA’s largest rail contract in Asia Pacific then. PT Len Industri and the rail operators evaluated all available options, and determined that the open source communication architecture used by HIMA equipment was the way to future-proof their investments, and to integrate new HIMA equipment seamlessly with legacy systems and technologies from other vendors.

Upgrading the Cikarang-Cikampek rail for highest safety standards

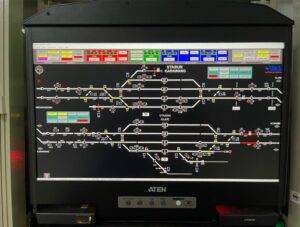

A step up from this collaboration, PT Len Industri and PT Len Railway Systems replaced the existing interlocking systems at the Cikarang-Cikampek rail to maximum safety and reliability.

The Cikarang-Cikampek rail runs a long-distance train service from both the eastern trip of Java Island and Bandung. The congested traffic can be a challenge for operators as minor issues in signaling systems can escalate to significant impact or even damages. Delays and long queues at the station had happened before when the legacy interlocking system was disrupted, primarily due to memory buffer overflows.

The operator determined that the interlocking system had to be upgraded to ensure overall safety and operating efficiency. The legacy solid state interlocking (SSI) system was replaced with the latest SiLSafe 4000 signaling system provided by PT Len Industri. The new interlocking system is powered by the HIMA HIMax safety system with the high-performance and uninterrupted safety controller. The HIMax solution enables multi-tasking from up to 32 independent applications and is certified in accordance with the Safety Integrity Level (SIL) 4 requirements by CENELEC, the European Committee for Electrotechnical Standardisation, formed from committees of 34 European nations.

Successful switch-over to new safety systems in just 30 minutes

Completed in December 2021, the replacement of the signaling and telecommunication system project was conducted in 8 stations along the Cikarang-Cikampek rail, namely Cikarang, Lemahabang, Kedunggede, Karawang, Klari, Kosambi, Dawuan, and Cikampek, on active and ongoing railway lines. While the construction process took 10 months, the switch-over process was successfully carried out in just 30 minutes.

The switch-over process included the deactivating of the existing SSI signaling system to activating the new SiLSafe 4000 signaling system. With only 30 minutes, integrators had to ensure that sufficient manpower and precise strategies were in place before the switching process. Additionally, the replacement of the existing interlocking system was followed by a change in the operating pattern of the train route. Originally reaching only to the Cikarang station, this replacement further supports the expansion of the operating facilities to reach the Karawang station.

“As automation and interconnectivity become prevalent in the rail industry, companies are under increasing pressure to modernise and integrate with the latest technologies. PT Len Industri and PT Len Railway Systems are leaders and innovators who leap away from outdated proprietary technologies and adopt future-proof safety and security systems for rail operators. Their choice of HIMA’s HIMax to replace antiquated systems was an excellent decision during this extremely tight schedule and rough operating conditions,” added Best.

###

領先印尼鐵路系統供應商 PT Len 鐵路聯合德國HIMA系統提供西爪哇芝卡朗-奇坎佩克鐵路的最高安全標準

臺灣 – 印尼最大的鐵路應用和安全系統提供商PT Len Industri(Persero)及其子公司PT Len Railway Systems(LRS)已成功升級印尼的西爪哇芝卡朗-奇坎佩克(Cikarang-Cikampek)鐵路服務的信號和電信系統,以符合當前和新興的安全標準。

“鐵路行業是亞太地區許多經濟體和企業的關鍵血脈。印尼也在建設關鍵的鐵路基礎設施,爲區域城市提供高效且具有成本效益的供應鏈和消費者運輸。完整且可持續的鐵路系統包括基礎設施、信號、運營、人員和維護。隨着鐵路網絡的發展和增長,鐵路供應商和運營商需要達到行業和全球安全和網絡安全標準,以降低風險並向利益相關者保證,” HIMA亞太區副總裁Friedhelm Best說。”鐵路運營商有一種趨勢,即在運營中走向獨立,並且擁有能夠獨立運行的系統,運營商和供應商將需要提供能夠100%兼容和可靠性的互操作性和解決方案,以及未來符合標準和偏好的產品和解決方案。

PT Len Industri 加強與HIMA的關係

2016年,HIMA與PT Len Industri簽署了一項重要戰略合同,以價值180萬歐元的價格升級印尼25個火車站的安全技術,這是HIMA當時在亞太地區最大的鐵路合同。PT Len Industri和鐵路運營商評估了所有可用的選項,並確定HIMA設備使用的開源通信架構是使其投資未來趨勢的最佳方式,並將新的HIMA設備與其他供應商的遺留系統和技術無縫集成。

升級 Cikarang-Cikampek 鐵路,達到最高安全標準

這次合作中向前邁出的一步,即是PT Len Industri和PT Len Railway Systems取代了Cikarang-Cikampek鐵路上現有的聯鎖系統,以最大限度地提高安全性和可靠性。

Cikarang-Cikampek鐵路從爪哇島和萬隆的東部旅行中運行長途火車服務。擁堵的交通擁堵對運營商來說是一個挑戰,因爲信號系統中的小問題可能會升級爲重大影響甚至損壞。在車站的延誤和長隊之前,當傳統的聯鎖系統中斷時,主要由於內存緩衝區不足。

操作員確定必須升級聯鎖系統,以確保整體安全性和操作效率。傳統的固態聯鎖(SSI)系統被PT Len Industri提供的最新SiLSafe 4000信號系統所取代。新的聯鎖系統由HIMA HIMax安全系統提供動力,該系統具有高性能和不間斷的安全控制器。HIMax解決方案支持來自多達32個獨立應用程序的多任務處理,並通過了歐洲電工標準化委員會CENELEC的安全完整性等級(SIL)4要求認證。該委員會由34個歐洲國家的委員會組成。

在短短 30 分鐘內成功切換到新的安全系統

2021年12月完成的信號和電信系統項目的更換,在Cikarang-Cikampek鐵路沿線的8個車站進行,分別是Cikarang,Lemahabang,Kedunggede,Karawang,Klari,Kosambi,Dawuan和Cikampek,皆爲正在運營使用中的鐵道。雖然施工過程耗時 10 個月,但切換過程僅30 分鐘即完成。

切換過程包括停用現有的SSI信號系統,以激活新的SiLSafe 4000信號系統。只需30分鐘,集成商就必須確保在轉換過程之前有足夠的人力和精確的策略。在更換現有的聯鎖系統之後,火車路線的運行模式有了改變。最初只到達芝卡朗站,這一替代進一步支持了運營設施的擴展,以到達加拉璜站。

“隨着自動化和互聯性在鐵路行業日益普及,企業面臨着越來越大的壓力,需要現代化並與最新技術集成。PT Len Industri 和PT Len Railway Systems是領導者和創新者,他們從過時的專有技術中躍升,爲鐵路運營商提供面向未來的安全和安保系統。他們選擇HIMA的 HIMax 來取代過時的系統,在這個極其緊張的時間表和惡劣的運行條件下,這是一個極好的決定,” Best補充道。

###