What To Know

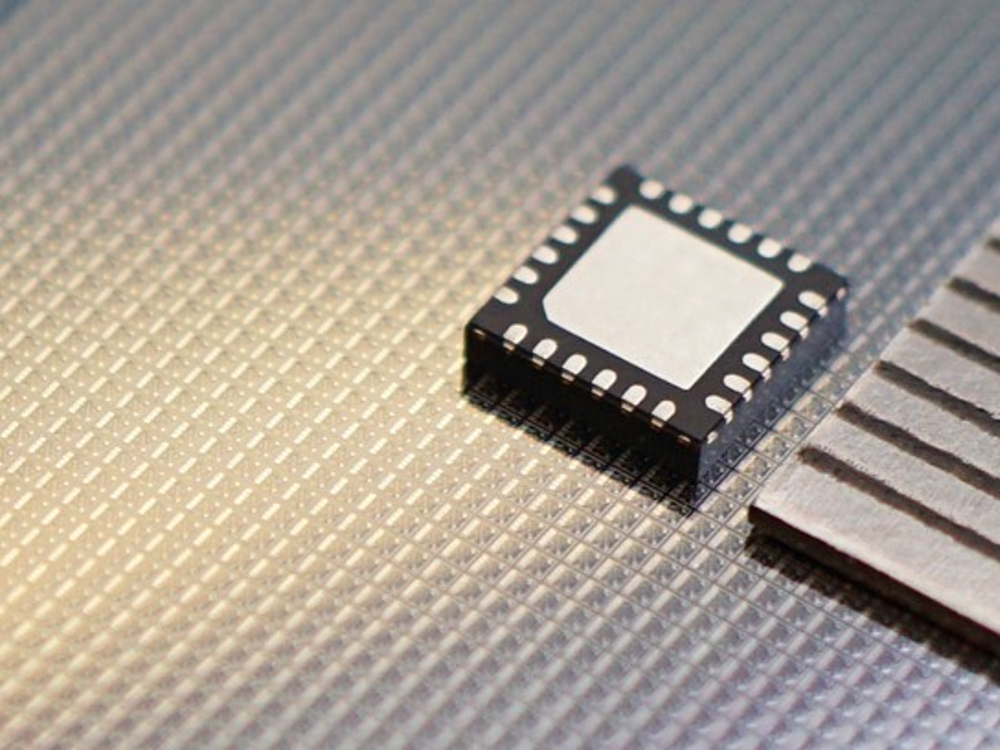

- Due to the increasing prevalence of cybersecurity threats and the need for remote management, HIMA has recommended the newer HIQuad X, released in 2018, for extending the speed, reliability, and safety features of the original HIQuad with new security and maintenance friendliness features.

- To reduce the amount of time spent on-site working and offline, the HIMA engineering team meticulously planned the implementation and carried out all necessary tests, from hardware to simulated communications in the lab to logic testing in the field.

Editor’s brief: The chemicals industry is deeply entrenched in not just petrochemicals and polymers, but also important pharmaceuticals and medical industries, including being part of the supply chain of personal protective equipment, masks, sanitizer, and industrial hygiene and cleaning. For critical infrastructures such as energy and chemicals industries, some of the lesser talked about subjects are safety and cybersecurity in relation to modernization. A good example is how a leading chemicals giant managed to modernize their industry safety systems quickly with German Smart Safety company HIMA, with provisions for both real-time safety and cybersecurity.

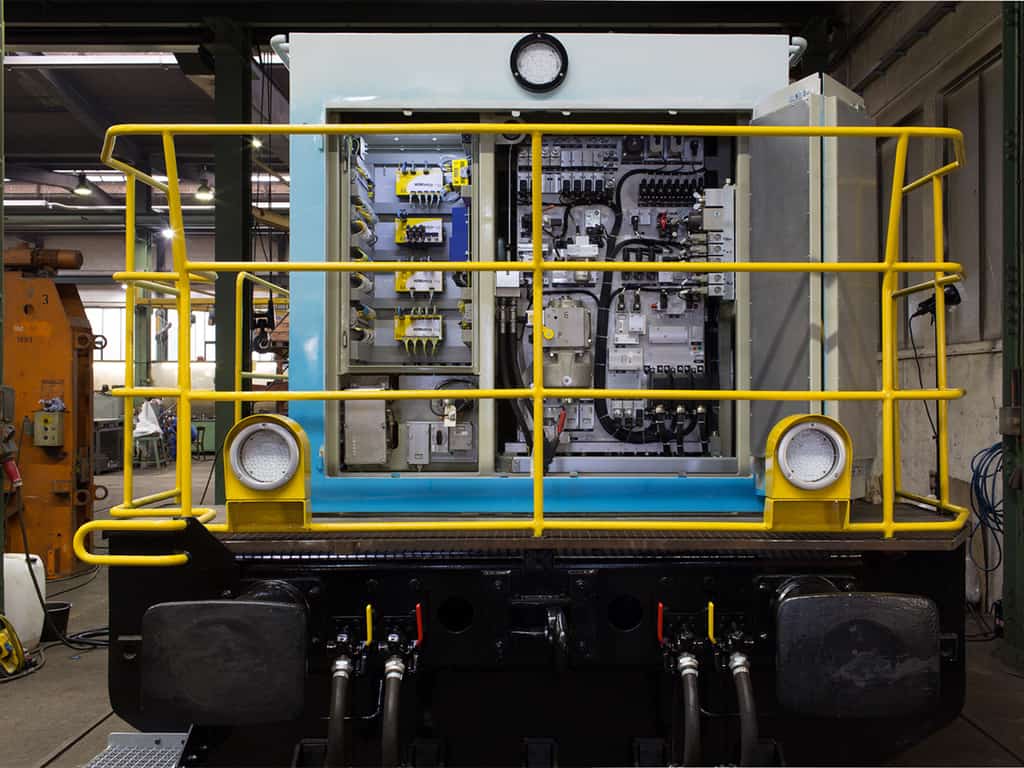

SINGAPORE – Ningbo ZRCC Lyondell Chemical Co., Ltd. (Ningbo ZRCC) has successfully upgraded its safety instrumented systems (SIS) to HIQuad X from leading German industrial safety and security leader HIMA. Ningbo ZRCC is the first in China to use the leading-edge HIMA HIQuad X for advanced industrial safety and cybersecurity features.

Ningbo ZRCC produces 285,000 tons of propylene oxide and 620,000 tons of styrene per year, as one of the largest propylene oxide and styrene production units in the world.

Future-proofing with enhanced speed, safety and cybersecurity

Using HIMA HIQuad, Ningbo ZRCC has been a satisfied customer for many years. Ningbo ZRCC reached out to HIMA in early 2019 to upgrade its 10 HIQuad safety instrumented systems in light of its growing sewage treatment and future-proofing requirements (SIS). Additionally, Ningbo ZRCC’s waste alkali incinerator required additional HIQuad safety interlocks.

Due to the increasing prevalence of cybersecurity threats and the need for remote management, HIMA has recommended the newer HIQuad X, released in 2018, for extending the speed, reliability, and safety features of the original HIQuad with new security and maintenance friendliness features. HIMA also suggested using the TUV-approved SILworX engineering tool platform for simple coding and management of the HIQuad X systems. In addition, the upgraded system must be able to keep exchanging data in a safe and reliable manner with the original system in order to satisfy the security requirement.

6 days to success with minimal downtime

HIMA’s engineering department and after-sales service team visited Ningbo ZRCC’s site after management approval, where they devised an implementation plan that prioritized efficiency, safety, regulatory compliance, and minimal downtime.

Ningbo ZRCC is a critical facility, so it was imperative that the upgrade to HIQuad X go off without a hitch and in complete safety. To reduce the amount of time spent on-site working and offline, the HIMA engineering team meticulously planned the implementation and carried out all necessary tests, from hardware to simulated communications in the lab to logic testing in the field.

The fact that HIMA was able to complete on-site testing of hardware replacement, communication, and logic in just six days in June 2019 is a testament to the quality of both HIMA’s technologies and the engineering behind them.

Fast, cost-effective, easy to manage, and secure

Customers typically anticipate that automated systems, such as safety installations, will last more than two decades while still adhering to modern standards. It can be difficult to implement upgrades in a system that runs nonstop around the clock but requires maintenance every three to five years, which could cause disruptions. Using HIMA’s modular technologies, Ningbo ZRCC was able to gradually update their facility while keeping the rest of the facility operational through scheduled maintenance outages of individual units.

As expected of such critical infrastructure, the HIMA HIQuad installation at Ningbo ZRCC has been up and running for more than a decade without a single hiccup. The entire field cabling was left untouched during the upgrade to HIQuad X, but the processing units, communication units, and the I/O bus were all replaced with new state-of-the-art HIQuad X technology to ensure compliance with the most recent safety and security recommendations.

The result of these upgrades is a safety network in which multiple controllers can respond to emergencies in unison. HIMA Safe Ethernet technology was used in the upgraded installation to run the HIPRO-S V2 and provide a secure, TÜV-approved security solution that would allow for the simultaneous and seamless running of technologies that had been developed over the course of 20 years.

“Thanks to the elegantly simple and speedy upgrade from HIQuad to HIQuad X, we can leverage the most advanced safety technology to ensure the safety of our plant within a limited time and budget. After the upgrade, we realized a tremendous upgrade in operating speed, especially with the upgraded system’s use of the engineering management platform SILworX, providing us with comprehensive data overview, ease of operation, and convenience,” said Ningbo ZRCC’s engineering spokesperson.

“We at HIMA understand what mission-critical operations such as Ningbo ZRCC requires, and we supported their challenging plan to do a stepwise modernization of their HiQuad to HiQuad X installation. This was possible because of the effectiveness of HIMA’s product strategy, combining long-lasting product lifecycles, full compatibility of products from different generations, and a comprehensive service portfolio supporting our clients. We are always ready to help our clients achieve the highest performance for their investments in safety technologies,” said Peter Sieber, HCH GM, HIMA.

###

Microwire.news (aka microwire.info) is a content outreach and amplification platform for news, events, brief product and service reviews, commentaries, and analyses in the relevant industries. Part of McGallen & Bolden Group initiative. Copyrights belong to the respective authors/owners and the news service is not responsible for the content presented.